THIXOMOLDING: LIGHTWEIGHT, THIN-WALLED, STRONG METAL PARTS

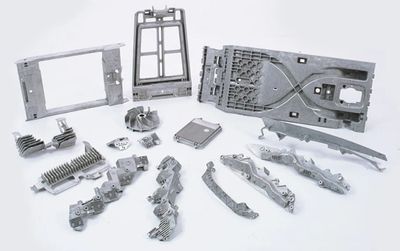

Thixomolding is a unique manufacturing process that allows manufacturers to design highly complex, light weight parts from magnesium alloys for medium to high volume applications. It is not new process and has been used in the automotive, consumer products, drone, telecom, etc. industries for many years.

Thixomolding is high-pressure injection molding of a semi-molten magnesium alloy and MIM is a powdered/sintered metal process.

Thixomolding injects a magnesium alloy slurry at extremely high velocities into a mold that reduces voids. A properly designed part will have very high yields, excellent part detail, superb metallurgical structure, and tight tolerance capability when compared to magnesium die casting.

The concepts and theories behind designing parts for Thixomolding is more similar to plastic injection molding rather than die-casting. In fact, if you are familiar with plastic injection molding you are about 80% of the way to designing Thixomolded parts. We recommend that our customers design their parts for plastic injection molding and then let GTI help you optimize the final Thixomolding design for manufacturing.

THIXOMOLDING ADVANTAGES

INDUSTRIES USING THIXOMOLDING

INDUSTRIES USING THIXOMOLDING

- Dimensional Precision

- Thin Wall Capability (>0.040" 1mm)

- Lightweight

- Complex Net Shapes

- Excellent, Cosmetic Surface Finish

- Reduced Secondary Operations

- Low Porosity

- High Volume

- Variety of Finishes Available

- Competitive Pricing

- Global Supply Chain

- EMI/RFI Shielding

- Excellent machinability

INDUSTRIES USING THIXOMOLDING

INDUSTRIES USING THIXOMOLDING

INDUSTRIES USING THIXOMOLDING

- Automotive

- Lighting, interior and exterior

- Interior components

- Frames

- Housings

- Computer Peripherals

- Consumer Electronics

- Drones

- Medical Devices

- Body Mounted Devices

- Handheld devices

- Missile Components

- Aircraft components

- Firearms

Mg vs. Plastic

Mg vs Die Casting

Mg vs Die Casting

- 10-20x Stiffer

- Dramatically Stronger

- Similar Part Complexities & Geometries

- Potentially Lighter Parts

- Elimination of EMI/RFI Shielding Operations

- Part Consolidation

Mg vs Die Casting

Mg vs Die Casting

Mg vs Die Casting

- Lower Costs

- >30% Lighter than Al

- >50% Lighter than Zn

- Reduction and/or Elimination of Secondary Operations

- Lower Overall Tooling Costs

- Thinner Walls

- Better Metallurgical Properties

- Part Consolidation

- Superior Corrosion Resistance

Can You Machine Magnesium?

YES WE CAN!!

We machine it all of the time.

Whether 100% machining or machining of die-casting, we can do it. Many of our customers opt for machined prototypes to validate parts before approving thixomolding or die cast tooling.

Plus our magnesium machining operations are located in Puerto Rico or China depending on your requirements.