Die Casting - Aluminum and Magnesium

Almost every design and mechanical engineer is versed in aluminum die casting. We find that engineering, program management, and procurement have different objectives and concerns and, more often than not, these are not communicated which creates issues. GTI's technical and commercial managers bring these functions together to educate the team on their options and to help them determine a complete solution.

If your parts benefit from magnesium die casting then it is ever so important that GTI helps you through this process.

Die Casting - Aluminum & Magnsesium

That is what we do

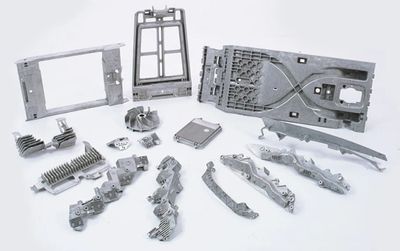

GTI has developed a global supplier network that includes aluminum, magnesium, and zinc die casting with machines up to 1,600 tons, specialties with:

- Large parts

- Thin wall and complex geometries

- Automotive, consumer products, power tool, and telecom applications

- ISO and TS certification

- Secondary processes include automated CNC machining and a variety of coating options

Often engineers determine a parts' manufacturing process early on in the design cycle. We have learned that you certainly need to have an idea of how to process the part, however team evaluates geometries, total cost of ownership, logistics, and experience to make sure the part is optimized.

Tooling

GTI also offer quick turn, high quality, die casting tooling for international delivery.